CONTACTS

+86 13365317763Weifang Haoli Membrane Structure Engineering Co., Ltd.

Contact Person: Ms Linda Ren

Phone& whatsapp&wechat no.: +8613365317763

Email Address: 1017546800@qq.com

ETFE

+86 13365317763

+86 13365317763

Weifang Haoli Membrane Structure Engineering Co., Ltd.

Weifang Haoli Membrane Structure Engineering Co., Ltd.

山东省潍坊市临朐县城南街道朱封工业园内

山东省潍坊市临朐县城南街道朱封工业园内

2022-8-26

2022-8-26

637

637

Information

ETFE:( Poly (ethene-co-tetrafluoroethene))

Parameters Table:

Parameter | Company | Test method | Technical Specifications | Actual Average |

Thickness (Tolerance) | Micron (%) | ISO4593 (ISO4593) | 250 (+/3%) | - |

Breaking strength (longitudinal/Transverse) | Mpa | EN ISO 527-3 | >40/ > 40 | 47/47 |

Elongation at break (longitudinal/Transverse) | % | > 300/> 300 | 369/375 | |

Yield stress - 10% | Mpa | >22 | 24 | |

Tensile modulus of elasticity - 1% | Mpa | >900 | 1005 | |

Tear strength | N/mm | DIN 53363 | >450 | 461 |

Creep test longitudinal | % | 8.6EM13206 | 0.5 | - |

Visible Light Transmitted (380:780nm) | % | EN2155-5 | 89 | - |

Flame retardant grade | DIN 4102 B1-ASTM E108-A | |||

Item | Test mathod | Values | Units |

Tensile strength/ (M.D) | EN ISO 527-3 | >50 | Mpa |

| Tensile strength/ (T.D) | EN ISO 527-3 | >50 | Mpa |

| Tensile strain at break/ (M.D) | EN ISO 527-3 | >300 | % |

| Tensile strain at break/ (T.D) | EN ISO 527-3 | >300 | % |

| Yield stress | EN ISO 527-3 | >22 | Mpa |

| Tensile modulus | EN ISO 527-3 | >9 | Mpa |

| Tear resistance | DIN 53363 | >450 | N/mm |

| Creep test | 8.6 EN 13206 | 0.5 | % |

| Dart drop test | Int.method (lo 82.4002) | >15 | kg |

| Transparent visible transmittance | EN 2155-5 | 89 | % |

| Blue visible transmittance | EN 2155-5 | 60 | % |

| Printed visible transmittance | EN 2155-5 | 64 | % |

| Color transmittance | EN 2155-5 | 30-50 | % |

| Thickness | ISO 4593 | 250 | μ m |

| Width | ISO 4592 | 150-200 | cm |

| Fire behaviour | DIN 4102 | B1 | B1 |

| Temperature range | - | -200~+150 | ℃ |

| Melting point | EN ISO 12086 | 270 | ℃ |

| Melting heat | - | 40 | Kcal/kg |

| Thermal conductivity | - | 0.25 | W/m℃ |

| Surface tension | Geometric | 30 | Dyne/cm |

| Weight | Int.method | 437 | g/㎡ |

| linear thermal expansion | - | 0.9 | mm/m℃ |

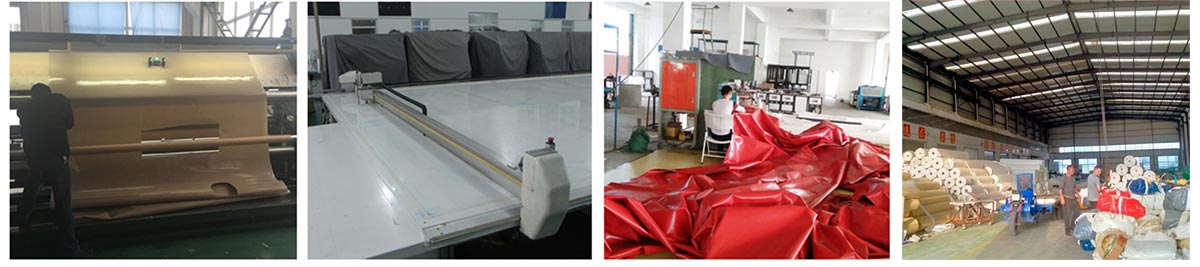

Manufacturing:

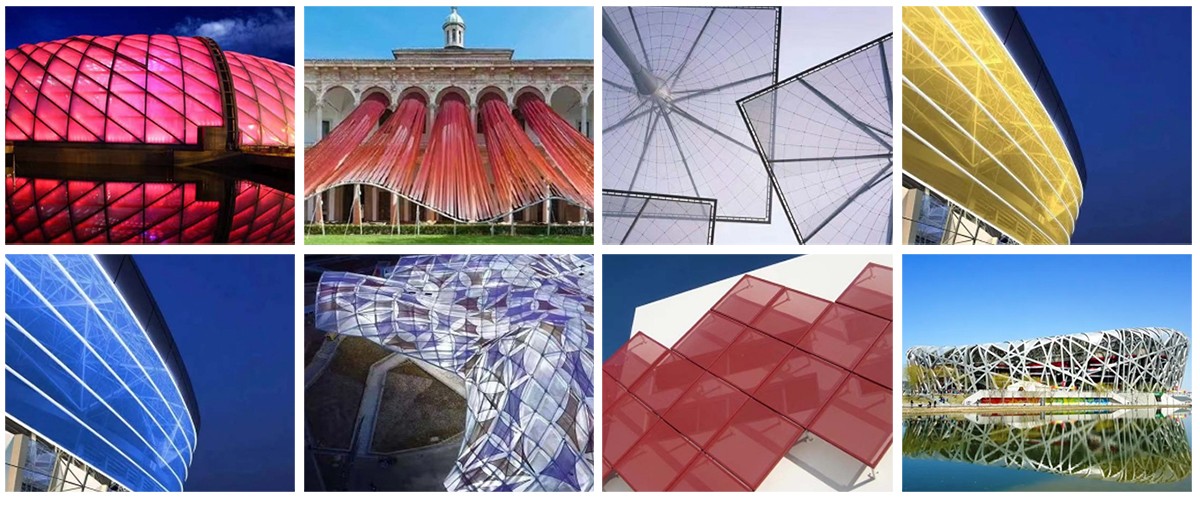

Case Show:

Current Location:

Current Location:

Hot Line:+86 13365317763

Hot Line:+86 13365317763

ETFE

ETFE

首页

首页

产品

产品

电话

电话